In recent years, 3d scanning has revolutionized the field of product design. No longer confined to large-scale industrial applications or the world of high-end manufacturing, 3D scanning has become a valuable tool for designers across industries. This technology allows designers to transform physical objects into highly detailed digital models, enabling them to streamline workflows, improve accuracy, and enhance creativity. Let’s take a closer look at how 3D scanning is shaping product design, from the early conceptual stages to final production.

The Rise of 3D Scanning in Product Design

Traditionally, product designers would sketch their ideas by hand or use CAD (Computer-Aided Design) software to create models from scratch. However, as digital technology continues to advance, 3D scanning has become a game-changer in how designers approach the creation of new products. By scanning real-world objects and converting them into digital models, designers can work with accurate representations of existing products, improve iterations, and modify features without starting from zero.

From Physical Objects to Digital Models

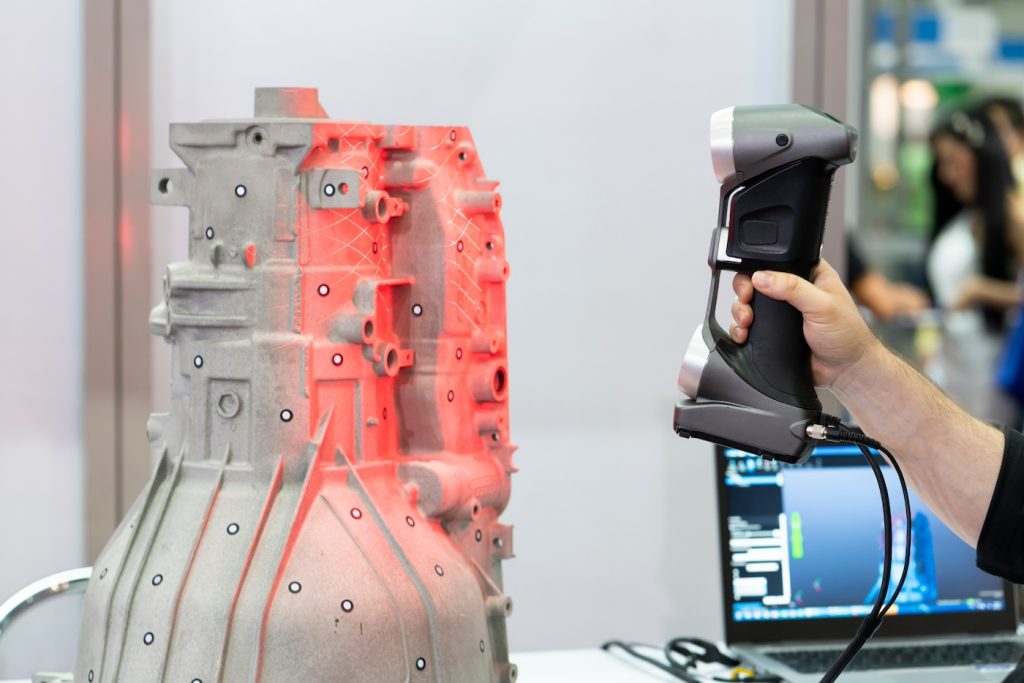

The fundamental concept behind 3D scanning is to capture the geometry of a physical object and translate it into a digital 3D model. This is done by using a variety of scanning techniques such as laser scanning, structured light scanning, and photogrammetry. The data collected during the scanning process is then processed and converted into a mesh of points or polygons, which can be used for further design and manufacturing purposes.

The accuracy and level of detail that modern 3D scanning technologies offer make them an ideal tool for industries like automotive, aerospace, and consumer electronics. Designers can now capture complex shapes, textures, and intricate details in a matter of minutes. This process not only speeds up the design cycle but also ensures that the digital model is a precise representation of the physical object.

Improving Product Design Iterations

One of the most significant advantages of 3D scanning in product design is its ability to support rapid iteration. Traditionally, creating prototypes for each design change would require time-consuming manual work and additional resources. With 3D scanning, designers can quickly capture the geometry of prototypes or existing products, modify the digital model, and test variations with minimal effort.

The iterative process becomes much more efficient when designers can easily compare the scanned model with their original design. For instance, if a designer wants to improve the ergonomics of a product, they can scan an existing prototype, tweak the design based on feedback, and then use the scan data to create a new iteration without starting from scratch.

Real-World Data for Better Design Decisions

When designers use 3D scanning, they are working with real-world data rather than theoretical models. This is particularly valuable when designing products that need to interact seamlessly with other products or systems. For example, when designing a new part that must fit into an existing assembly, scanning the current assembly allows the designer to identify potential fit issues early in the design process.

By using accurate digital representations of real-world objects, designers can make more informed decisions about material selection, fit, and performance. This reduces the risk of costly errors during production and ensures that the final product is well-optimized for both function and aesthetics.

Enhancing Collaboration and Customization

Another key benefit of 3D scanning in product design is its ability to enhance collaboration. Designers, engineers, and manufacturers can all access the same digital model, which facilitates a more collaborative workflow. Whether working remotely or on-site, team members can view, modify, and comment on the 3D model, making it easier to share ideas and track progress.

In addition to collaboration, 3D scanning opens the door to mass customization. With 3D scanning, companies can create products tailored to individual needs or preferences. This is especially important in industries like fashion, healthcare, and automotive, where personalized products are in high demand. By scanning a customer’s body, for example, clothing manufacturers can design garments that fit perfectly, while automotive companies can customize vehicle parts to meet specific customer requirements.

The Future of 3D Scanning in Product Design

As technology continues to evolve, the potential applications of 3D scanning in product design are only set to grow. With advancements in scanning accuracy, resolution, and processing speed, designers will have even more powerful tools at their disposal to bring their ideas to life.

Moreover, as 3D printing continues to gain popularity, the connection between 3D scanning and additive manufacturing is becoming increasingly important. Scanned models can be directly translated into printable 3D files, enabling faster prototyping and low-volume production runs. The combination of 3D scanning and 3D printing has the potential to completely disrupt traditional product design and manufacturing processes.

Conclusion

From objects to models, 3D scanning is undeniably shaping the future of product design. The ability to quickly and accurately digitize physical objects, make real-time modifications, and collaborate seamlessly across teams offers unprecedented flexibility and efficiency in the design process. As this technology advances, the possibilities for product designers are limitless, promising a new era of creativity, precision, and innovation.